| Sign In | Join Free | My chinacomputerparts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacomputerparts.com |

|

Brand Name : Shine Abrasives

Model Number : 4V2 1A1 14A2

Certification : ISO

Place of Origin : China

MOQ : 2 pcs

Price : FOB

Payment Terms : L/C, T/T

Supply Ability : 1000 PCS in one week

Delivery Time : 5 work days

Packaging Details : one in paperbox

Cooling Method : Water or Oil

Coolant Required : Yes

Edge Type : Sharp

Arbor Hole : standard

Precision : High

Grit : 180#

Bore : 1/2 inch-12.7mm

Payment Term : T/T, L/C, Western Union, Paypal

Availability : In Stock

Viscosity : Electroplated Bond Diamond

Bond : Metal

Usage : Wet/Dry

Bonding Material : Nickel

Feature : High Efficiency

Service : Excellent

Using a CBN wheel can be a highly effective and efficient way to maintain the sharpness and cutting performance of your wood bandsaw blades, leading to smoother, more accurate cuts and extended blade life.After sharpening, clean the blade thoroughly and apply a light lubricant. When selecting a CBN wheel for bandsaw blade sharpening, consider factors such as wheel grit size, diameter, and speed compatibility with your grinder. Consult the manufacturer's recommendations to ensure the wheel is suitable for your specific application and equipment.

| Product Name | Diameter | Grit | Angle | Usage |

| electroplated CBN diamond grinding wheel | 127mm | B126 B151 Customized | 10/30, 9/29, 13/29, 4/32, 7/34 | for Band Saw Blade |

| 150mm | ||||

| 203mm | ||||

| Customized |

Set up a bench grinder or dedicated sharpening station with the CBN wheel.

Secure the bandsaw blade in a sharpening jig or guide to maintain the correct sharpening angle.

Gently and slowly bring the blade into contact with the rotating CBN wheel, applying light, even pressure.

Sharpen each tooth, ensuring a consistent angle and shape across the entire blade length.

Avoid excessive heating of the blade by taking breaks and using coolant as needed.

|

|

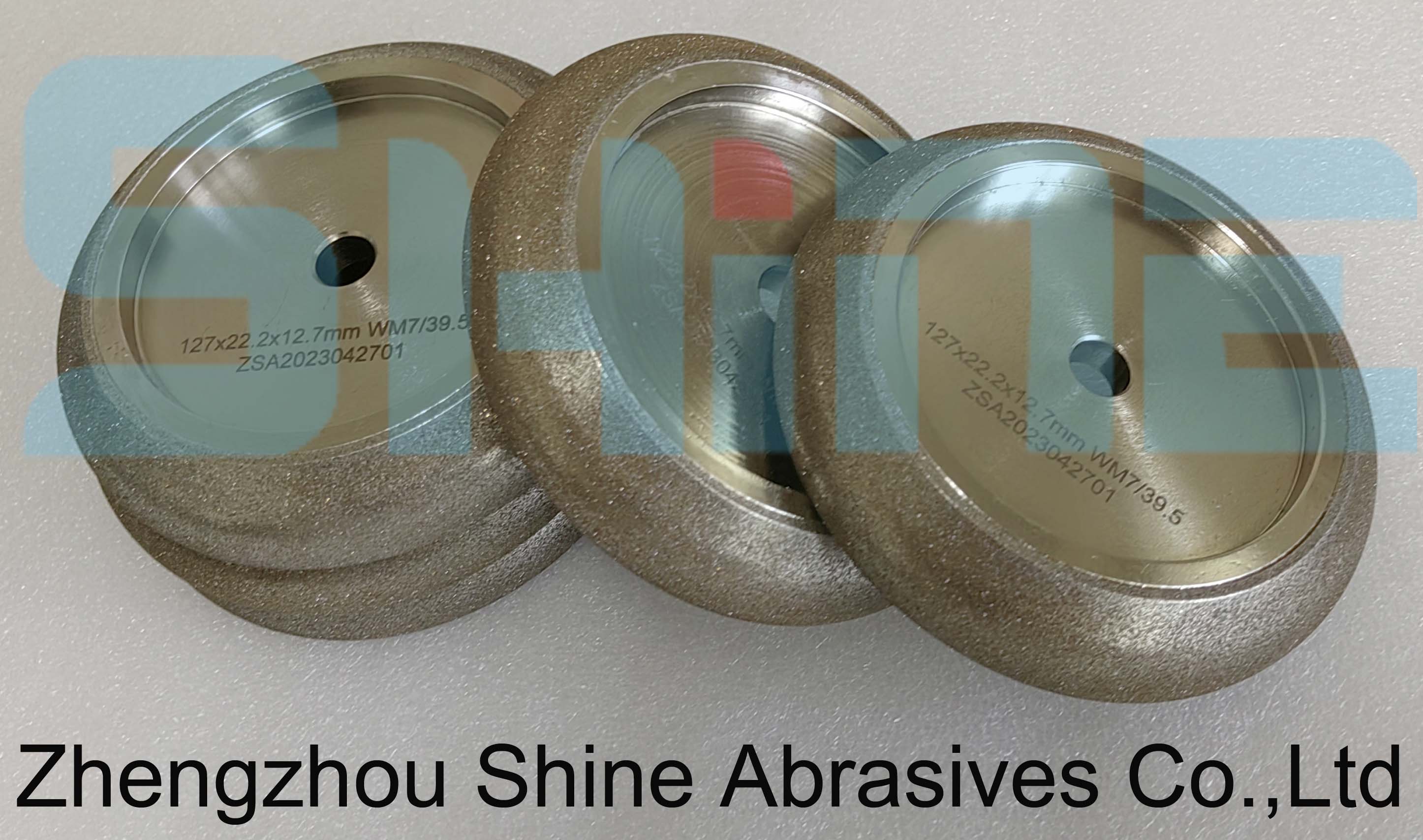

OEM 127mm Electroplated CBN Wheel For Bandsaw Blade Sharpening Images |